Kholee Blast offers manual drying sand blasting cabinet with turntable, which is used to remove rust, oxide layers, paint film from castings, welding parts, heat treatment parts and improve roughness.

Character

- special design and easy operation

- auto abrasive recovery, good air discharge and high temperature resistance.

- according to the requirements of dies/mold, the blasting strength can be adjusted.

- key parts adopts imported material, long life service

- cyclone separator which can separate dust and sand efficiently.

- electroplating, spraying process, improve adhesion; all kinds of mold, casting parts, metal, nonmetal surface heat treatment, to oxide skin, to residue, rust, oil, refurbished; all ceramic products, glass products, plastic products, light act the effect!

- special design of turntable with trails, load heavy products on turntable, convenient.

- loading capacity can be designed according to client requirements

Application

- clean oxide layers, burr and welding slag from heat treatment parts, welding parts, casting. The surface quality can reach sa3.0 after blasting.

- clean small burr and residues on machining parts

- do pre-treatment to parts before coating, which can improve adhesive of coating film.

- improve physical and mechanical properties such as surface stresses, lubricating conditions of mating parts

- improve roughness, finishing processes

- surface peening and eliminate stress

- renew old parts

- clean mould/die, no damage to the surface of mould/die, guarantee precision of mould and improve products grades.

- heavy products blasting cleaning such as mould, gravity press die mould.

|

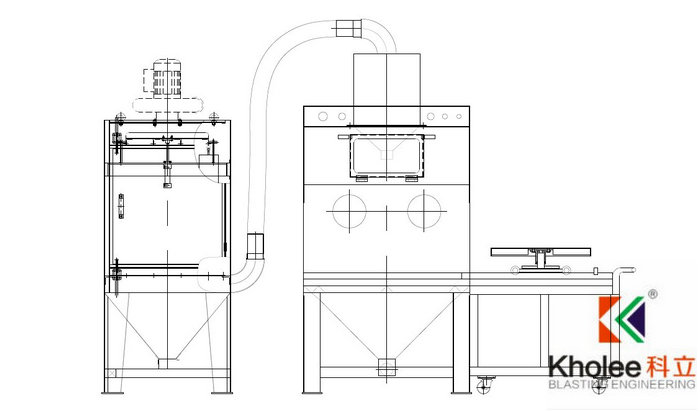

Manual Dry Sand Blast Cabinet with Turntable |

|||||

|

Model |

KL-BC9060T |

KL-BC9080T |

KL-BC1010T |

KL-BC1212T |

KL-BC1515T |

|

Working Cabinet Internal size(mm) |

900×600×660 |

900×800×700 |

1000×1000×790 |

1150×1190×930 |

1500×1500×930 |

|

TURNTABLE DIAMETER (MM) |

Φ500 ~ Φ700 |

||||

|

Turntable loading |

150 kgs |

||||

|

Whole Equipment size WITHOUT TURNTABLE (mm) |

900×1030×1560 |

900×1000×1900 |

1000×1540×1830 |

1200×1200×2200 |

1500×2000×2300 |

|

Dust Collector sizes(mm) |

600×600×1680 |

600×600×1680 |

600×600×1680 |

800×800×1680 |

800×800×1680 |

|

Side door size(mm) |

470×500 |

650×500 |

850×670 |

950×860 |

1250×1000 |

|

Front door size(mm) |

895×355 |

900×380 |

1000×380 |

1200×400 |

/ |

|

Power |

220V 50Hz |

220V 50Hz |

220V 50Hz |

220V 50Hz |

220V 50Hz |

|

Machine Light |

220V 13W |

220V 13W |

220V 13W |

220V 13W |

220V 13W |

|

Separator motor |

220V 50Hz 550W |

220V 50Hz 550W |

220V 50Hz 550W |

220V 50Hz 550W |

220V 50Hz 550W |

|

Separator air volume |

8.5 m3/min |

8.5 m3/min |

8.5 m3/min |

8.5 m3/min |

8.5 m3/min |

|

Compressed Air |

2-8bar |

2-8bar |

2-8bar |

2-8bar |

2-8bar |

|

Weight |

370kg |

370kg |

430 kg |

450kg |

650 kg |

Contacto:Carl Chen

Teléfono móvil: +86-139 1469 8671

Correo Electrónico:kholeeblast@gmail.com

Dirección:Dalong Industrial Park, Xituan, Dafeng, Yancheng, Jiangsu, China 224125

We chat