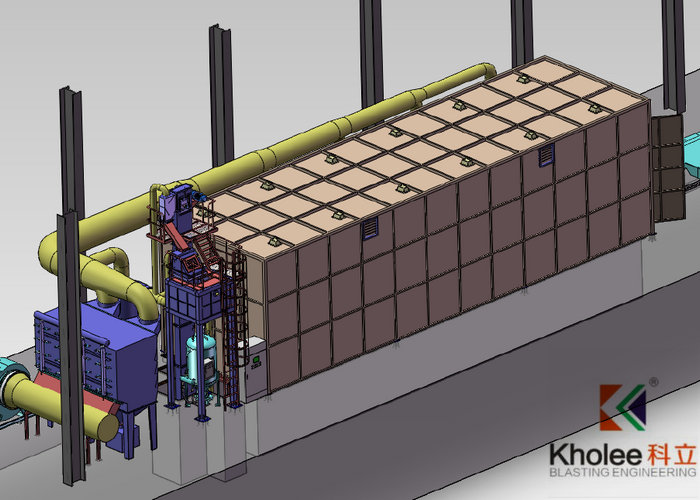

Blast room equipment is used in a wide variety of industries that require surface preparation prior to the application of a protective coating. The surface of the work-piece is cleaned by a mixture of abrasive and high pressure compressed air being directed on to the work piece by blast nozzle. The blast room contains the abrasive being shot at the work-piece, as well providing lighting and ventilation for the operator’s safety.

KHOLEE BLAST offers a variety of blast room designs and room configuarations which allow to design a blast room facility uniquely tailored to meet the economic production, safety and environmental concerns of each customer.

Shot blasting is one key technology of surface finishing in the industries of shipbuilding, steel structure, pressure vessel, pipelines, heavy engineering machinery etc. The productivity efficiencies of shot blasting equipments directly affects producing period; The coating quality directly affects the product service life.

This technical proposal meets the following requirements:

1) All systems of shot blasting are designed according to new coating standards. It must save the total invest cost as much as possible for the customer.

2) It meets the requirements of all weather operations and make sure it can do blasting in any climate conditions.

3) The design must take stability of equipments into consideration. It should meet the long time, full load operations as long as possible and reduce as much as possible the cost of repair and maintenance.

4) Adopt new technology and improve advanced nature of equipments and not increase the investment cost.

|

Electrical Power Voltage/Frequency |

Motor |

380V/50Hz |

|

Control |

220V/50Hz |

|

|

Size of Blasting Jobs |

Max Size |

15,000×2,000 ×3,000 mm |

|

Max Weight |

2~3 tons |

|

|

Blasting Room |

Door Open Size |

5,000×4,500mm |

|

Booth Size L × W × H |

18,000×5,000 ×5,000mm |

|

|

Blasting Productivity |

Working Time / Day |

8 hr.s |

|

Blasting Gun/ Φ10mm |

2 units |

|

|

Blasting Area per day |

15~35m2/hr×2×8hr.s =240~560m2 |

|

|

Surface Quality After Blasting (Decided by Steel Shots/Grits) |

Grade |

Sa 2.5 |

|

Roughness |

50µm~75µm |

|

|

Steel Shots/Grits |

Size |

1.0mm~1.2mm |

|

Initial Input |

4,000~5,000 kg |

|

|

Provided by the client |

||

|

Abrasive Recycle Type |

Auto-mechanic Shots Recycle System Belt Conveyor: 20 t/hr - 4kw Bucket Elevator: 50t/hr - 5.5kw Abrasive Dust Separator: 50t/hr |

|

|

Dust Removing System |

Air volume |

48500m3/hr |

|

Power |

45kw |

|

|

Pulse Jet Dust Collector |

LT4-64 |

|

|

Dust Emission Density |

80mg/m3 |

|

|

Noise Level |

≤85dB |

|

|

Illuminance |

≥300Lux |

|

Contacto:Carl Chen

Teléfono móvil: +86-139 1469 8671

Correo Electrónico:kholeeblast@gmail.com

Dirección:Dalong Industrial Park, Xituan, Dafeng, Yancheng, Jiangsu, China 224125

We chat