High carbon Steel Shot is used in the majority of the wheel blast applications and creates a dimpled, peened surface. Only the shot’s skin suffers from the impact and very thin flakes will progressively part from the shot, which itself stays round throughout its life cycle. Our steel shot is very durable with high resistance to impact fatigue, giving it an effective and quick cleaning rate.

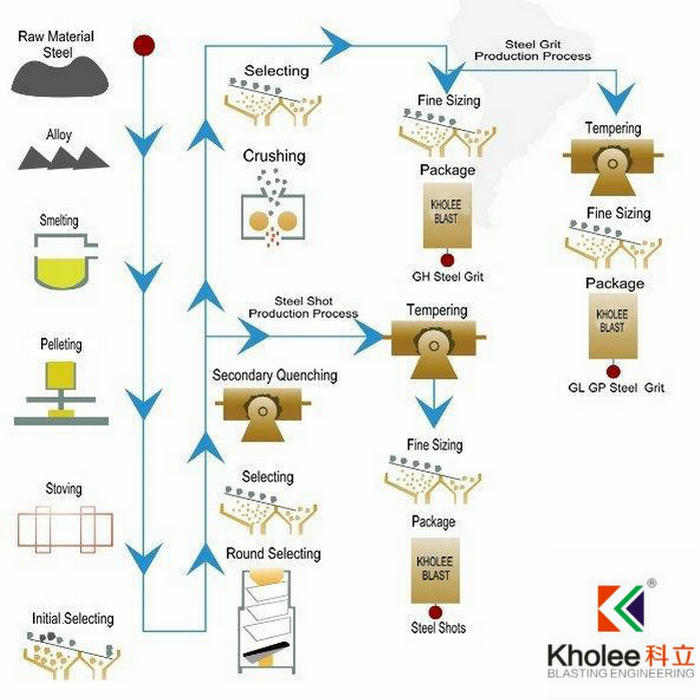

Our high carbon steel shot is used in various applications like; de-sanding, descaling, cleaning, shot peening etc.. The centrifugal atomization process and double heat treatment at the plants, as well as continues quality control measures, ensures the shot to be of the highest quality.

Operative Standards:

In accordance with standards of GB/T18838.3-2008 Steel Shot and Steel Grit,SFSA20-66Cast Steel Abrasive, SAE J827 Cast Steel Shot, SAE J1993High Carbon Steel Grit, YB/T5149-1993 Cast Steel Shot, YB/T5150-1993Cast Steel Grit,ISO11124-3High Carbon Cast Steel Shot and Grit.

|

Steel Shot |

Steel Grit |

Application |

|

S780/SS2.5 |

G10/SG2.5 |

Sand removal of large sized castings, scale removal of large sized products from forging, stamping, die forging, drawing and rolling or after heat treatment (e.g. pipes, sections, plates, fittings, wire). |

|

S660/SS2.0 |

G12/SG2.0 |

|

|

|

|

|

|

|

|

|

|

S550/SS1.7 |

G14/SG1.7 |

Sand removal of large and medium sized castings, scale removal of forging and heat-treated work pieces, surface blast cleaning of steel plates, sections and steel structures, shot peening of work pieces, cutting of granite. |

|

S460/SS1.4 |

G16/SG1.4 |

|

|

|

|

|

|

|

|

|

|

S390/SS1.2 |

G18/SG1.2 |

Sand removal of medium and small sized castings, surface blast cleaning of forgings, heat-treated pieces, steel pipes, sections and steel structures, surface treatment before painting, shot peening of work pieces. |

|

S330/SS1.0 |

G25/SG1.0 |

|

|

|

|

|

|

|

|

|

|

S280/SS0.8 |

G25/SG1.0 |

Surface blast cleaning of small sized castings, forgings and heat-treated pieces, aluminium and copper alloy castings, steel plates, steel pipes, sections and steel structures, shot peening of work pieces. |

|

S230/SS0.6 |

G40/SG0.7 |

|

|

|

|

|

|

|

|

|

|

S170/SS0.5 |

G50/SG0.4 |

Surface blast cleaning of stainless steel plates, thin steel plates, non -ferrous alloys, dacromet coat.

|

|

S110/SS0.3 |

G80/SG0.3 |

|

|

|

G120/SG0.2 |

Application Equipment

● Shot Blasting Machine (Auto Wheel Blasting Machine)

Steel Plate Shot Blasting Machine | Steel Structure Shot Blasting Machine | Steel Pipe Shot Blasting Machine | Hanger Type Shot Blasting Machine | Turntable Shot Blasting Machine | Tumble Belt Shot Blasting Machine | Overhead Conveyor Shot Blasting Machine | Steel Cylinder Shot Blasting Machine | Trolley Type Shot Blasting Machine | Wire Mesh Shot Blasting Machine etc.

● Blasting Room

● Sand Blasting Machine, Blasting Pot

● Shot Peening Machine

|

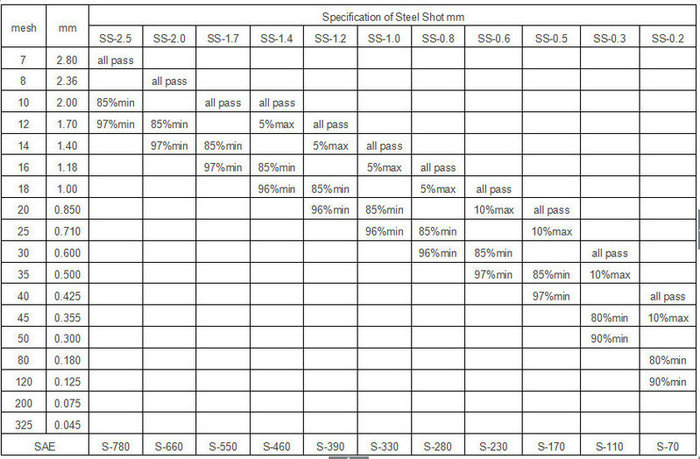

Specification of High Carbon Steel Shots |

|||||

|

Item |

C |

Si |

Mn |

S |

P |

|

Steel Shots |

0.85-1.20% |

0.40-1.20% |

0.60-1.20% |

<0.05% |

<0.05% |

|

Hardness |

40~50HRC | 52~56HRC | 56~60HRC, Max Deviation ±3.0 HRC |

||||

|

Density |

7.4 g/cm3 |

||||

|

Bulk Density |

4.4 g/cm3 |

||||

|

Ervin Cycle Times |

2800~3300 times |

||||

|

Micro-Structure |

Homogeneous Tempered Martensite or Troostite |

||||

|

Colour |

Dark Black |

||||

Contacto:Carl Chen

Teléfono móvil: +86-139 1469 8671

Correo Electrónico:kholeeblast@gmail.com

Dirección:Dalong Industrial Park, Xituan, Dafeng, Yancheng, Jiangsu, China 224125

We chat