High carbon Steel Grit produces an etched or angular surface profile and is well suited for cleaning, descaling, etching and de-sanding applications. Our high quality steel grit has a long service life and is used in both wheel blast machines and blast rooms.

Operative Standards:

In accordance with standards of GB/T18838.3-2008 Steel Shot and Steel Grit,SFSA20-66Cast Steel Abrasive, SAE J827 Cast Steel Shot, SAE J1993High Carbon Steel Grit, YB/T5149-1993 Cast Steel Shot, YB/T5150-1993Cast Steel Grit,ISO11124-3High Carbon Cast Steel Shot and Grit.

|

Steel Shot |

Steel Grit |

Application |

|

S780/SS2.5 |

G10/SG2.5 |

Sand removal of large sized castings, scale removal of large sized products from forging, stamping, die forging, drawing and rolling or after heat treatment (e.g. pipes, sections, plates, fittings, wire). |

|

S660/SS2.0 |

G12/SG2.0 |

|

|

|

|

|

|

|

|

|

|

S550/SS1.7 |

G14/SG1.7 |

Sand removal of large and medium sized castings, scale removal of forging and heat-treated work pieces, surface blast cleaning of steel plates, sections and steel structures, shot peening of work pieces, cutting of granite. |

|

S460/SS1.4 |

G16/SG1.4 |

|

|

|

|

|

|

|

|

|

|

S390/SS1.2 |

G18/SG1.2 |

Sand removal of medium and small sized castings, surface blast cleaning of forgings, heat-treated pieces, steel pipes, sections and steel structures, surface treatment before painting, shot peening of work pieces. |

|

S330/SS1.0 |

G25/SG1.0 |

|

|

|

|

|

|

|

|

|

|

S280/SS0.8 |

G25/SG1.0 |

Surface blast cleaning of small sized castings, forgings and heat-treated pieces, aluminium and copper alloy castings, steel plates, steel pipes, sections and steel structures, shot peening of work pieces. |

|

S230/SS0.6 |

G40/SG0.7 |

|

|

|

|

|

|

|

|

|

|

S170/SS0.5 |

G50/SG0.4 |

Surface blast cleaning of stainless steel plates, thin steel plates, non -ferrous alloys, decorate coat.

|

|

S110/SS0.3 |

G80/SG0.3 |

|

|

|

G120/SG0.2 |

● Shot Blasting Machine (Auto Wheel Blasting Machine)

Steel Plate Shot Blasting Machine | Steel Structure Shot Blasting Machine | Steel Pipe Shot Blasting Machine | Hanger Type Shot Blasting Machine | Turntable Shot Blasting Machine | Tumble Belt Shot Blasting Machine | Overhead Conveyor Shot Blasting Machine | Steel Cylinder Shot Blasting Machine | Trolley Type Shot Blasting Machine | Wire Mesh Shot Blasting Machine etc.

● Blasting Room

● Sand Blasting Machine, Blasting Pot

● Shot Peening Machine

|

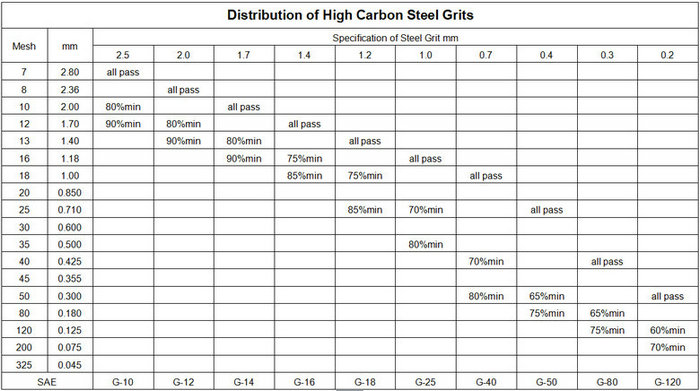

Specification of High Carbon Steel Grits |

|||||

|

Item |

C |

Si |

Mn |

S |

P |

|

Steel Grits |

0.85-1.20% |

0.40-1.20% |

0.60-1.20% |

<0.05% |

<0.05% |

|

Hardness |

GP: 42~50HRC | GL: 56~60HRC | GH: 63~66HRC | Max Deviation ±3.0 HRC |

||||

|

Density |

7.6 g/cm3 |

||||

|

Bulk Density |

4.2 g/cm3 |

||||

|

Micro-Structure |

Homogeneous Tempered Martensite or Troostite |

||||

|

Colour |

GP, GL: Dark Black | GH: Light Black |

||||

Contacto:Carl Chen

Teléfono móvil: +86-139 1469 8671

Correo Electrónico:kholeeblast@gmail.com

Dirección:Dalong Industrial Park, Xituan, Dafeng, Yancheng, Jiangsu, China 224125

We chat